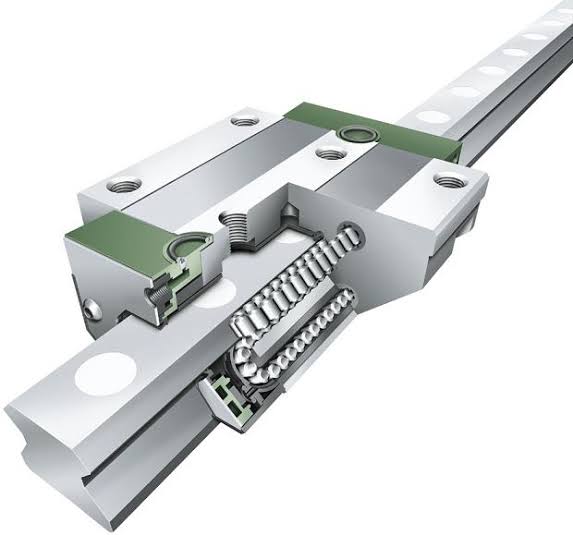

Are indispensable for ensuring smooth, precise linear motion in many industrial applications. Whether in robotics, materials handling, automation or machine tool production, linear guides play an essential role in the smooth operation of a wide range of equipment. Linear guides are made up of various components such as guide rails, carriages, ball bearings, ball screws, rollers and rollers. These elements enable linear motion to be guided and supported precisely and without excessive friction, guaranteeing high accuracy of movement and low component wear. The advantages of linear guidance systems are numerous. Firstly, they offer high motion accuracy, which is essential in many applications requiring high speeds or precise positions. Secondly, linear guides reduce friction between moving parts, ensuring greater rigidity and protection against wear.

Linear guidance systems are also designed to withstand hostile environments, such as corrosion or humidity. By using materials such as stainless steel or anodized aluminum, linear guides can be adapted to severe working conditions without compromising their efficiency. In addition, linear guides feature a high load capacity, making them suitable for applications requiring the movement of heavy loads. What’s more, these systems can be tailored to the specific needs of each application, whether in terms of lengths, speeds or types of movement. In short, the use of linear guidance systems is essential to ensure precise, smooth and reliable linear motion in many industrial applications. Thanks to their high precision, robustness and ability to withstand heavy loads, linear guides are a wise choice for any company seeking to optimize its production processes and ensure the reliability of its equipment.

Linear guidance systems are essential elements in many industrial and technical applications.

Thanks to their ability to enable smooth, precise linear motion, these systems are widely used in a variety of sectors, such as automation, machining, materials handling, precision agriculture, machine tools and many others. Linear guides are made up of rails and carriages, guided by balls, bearings, rollers or rollers, which ensure frictionless linear motion. They offer high precision, rigidity and load-carrying capacity, making them particularly suitable for applications requiring precise positioning at high speeds. Linear guidance systems are also used in demanding environments, such as corrosive atmospheres, extreme temperatures or high-wear conditions. Thanks to special materials such as stainless steel, anodized aluminum or bronze, these systems can resist corrosion and wear, and offer a long service life without the need for regular maintenance.Guide rails can be of various shapes, such as profiled, trapezoidal, cylindrical or square, offering modularity and adaptability to the specific needs of each application. In addition, linear guidance systems can be complemented by ball screws, toothed belts, transmission chains or cylinders to offer linear motion combined with other types of movement. In short, linear guidance systems can be used for a wide range of applications, from the automation of production lines to precision farming and the machining of complex parts. Their high precision, load-bearing capacity, rigidity and adaptability make them indispensable for many modern applications requiring smooth, precise linear motion.